Wrong steel shot size silently increases blasting cost.

Power use rises, dust collectors choke, and surface finish turns uneven. Many Indian foundries run shot blasting machines without clear rules for shot size, hardness, and replacement. This guide explains SAE J444 steel shot sizes, hardness limits, and maintenance practices proven on shop floors.

Why Steel Shots Matter in Foundry Cleaning

Steel shots remove sand, rust, and scale before painting or machining. In cast iron foundries, high carbon cast steel shots perform better than grit due to longer life and stable impact energy.

- Steel shots last 2000 to 3000 blasting cycles with proper recycling

- Dust collector load drops 15 to 25 percent compared to mixed abrasives

- Surface finish remains consistent across batches

Most small and medium Indian foundries operate efficiently with SAE S230 to S390 steel shots.

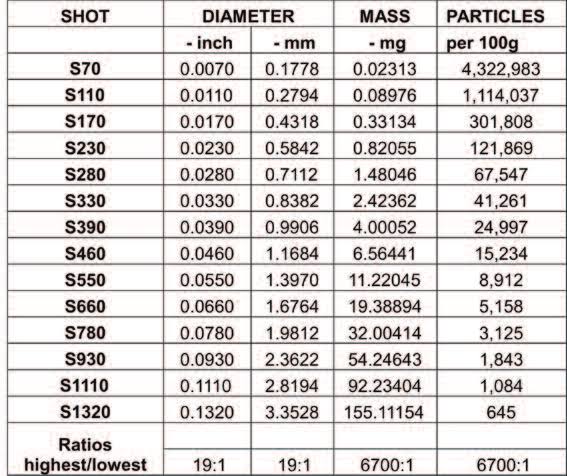

Steel Shot Sizes Chart. Complete SAE J444 Reference

This section covers all standard SAE J444 steel shot sizes from S110 to S780. Selecting the correct size avoids over blasting, excess power use, and fast wear of blast wheels and liners.

Fine Steel Shot Sizes. Light Cleaning and Detail Work

- S110 – 0.30 mm

Thin sheet metal, aluminum parts, light deburring, very small CI castings - S170 – 0.43 mm

Small castings, core sand removal, light rust cleaning - S230 – 0.58 mm

Thin CI castings, flash removal, smoother surface finish

Medium Steel Shot Sizes. General Foundry Use

- S280 – 0.71 mm

Valve bodies, pump housings, medium CI parts - S330 – 0.84 mm

Most widely used size in India. CI and SG iron castings with balanced cleaning and long shot life - S390 – 1.00 mm

Thicker sections with moderate to heavy scale

Coarse Steel Shot Sizes. Heavy Castings

- S460 – 1.18 mm

Large CI castings and rough surface profiles - S550 – 1.40 mm

Thick scale and heavy-duty descaling - S660 – 1.70 mm

Very heavy castings, limited use - S780 – 2.00 mm

Rare in India. Used only for extreme descaling

How to Select the Right Steel Shot Size

- Casting thickness below 6 mm. Use S110 to S230

- Casting thickness 6 to 25 mm. Use S280 to S330

- Casting thickness above 25 mm. Use S390 to S460

Do not mix fine and coarse sizes. Change sizes step by step to maintain stable blasting results.

Steel Shot Hardness HRC. Why It Matters

Hardness controls steel shot life, breakage rate, and dust generation.

- Ideal hardness range for cleaning. 40 to 50 HRC

- Below 38 HRC. Shots deform fast and lose impact

- Above 52 HRC. Shots break into fines and increase dust

How to Check Steel Shot Hardness

- Collect sample from hopper or elevator discharge

- Test broken shots using Rockwell hardness tester

- Check hardness at least once per month

Shot Peening vs Shot Blasting Steel Shots

- Shot blasting for cleaning uses 40 to 50 HRC

- Shot peening uses 55 HRC and above

Never mix peening shots with cleaning shots in the same machine.

Steel Shot Maintenance Routine for Foundries

Correct maintenance reduces abrasive cost by 20 to 30 percent.

Daily Checks

- Run magnetic separator continuously

- Remove broken shots and tramp metal

- Monitor dust collector pressure drop

Weekly Checks

- Screen and classify shot sizes

- Check fines percentage

- Inspect blast wheel liners and control cage

Monthly Checks

- Measure shot hardness

- Track shot makeup rate per shift

- Inspect elevator buckets and screws

Expected Steel Shot Life

- Tumblast machines. Up to 3000 cycles

- Spinner hanger machines. 2000 to 2500 cycles

When to Refill or Replace Steel Shots

Refill Rules

- Refill when shot level drops 15 to 20 percent

- Typical makeup rate. 2 to 5 percent per day

- Track consumption in kg per hour

Full Replacement Indicators

- Fines exceed 20 percent

- Hardness drops below 38 HRC

- Surface finish becomes dull

- Dust collector load rises sharply

Best Steel Shot Size for Indian Foundries

- Best all-round size. S330

- For heavy castings. S390

- Avoid mixing more than two sizes

Always buy SAE J444 compliant steel shots from certified suppliers. Non-standard shots increase dust, blast wheel wear, and operating cost.

Key Takeaways

- Match steel shot size to casting thickness

- Maintain hardness between 40 and 50 HRC

- Run separator and air wash daily

- Track shot makeup rate consistently

- Replace shots before fines exceed 20 percent

Correct steel shot selection and control lowers cost per casting and improves surface finish consistency in Indian foundries.